Metal Jacketed & Metal Corrugated Gaskets.For many years now, the metal jacketed gasket design has served industries sealing needs, providing a cost effective, quality seal with the introduction of improved gasket manufacturing processes and materials, this trend is deemed to continue for many more to come. Metal jacketed gaskets compromise of a soft/non asbestos material either partically or totally enveloped in a metallic sheath. This gasket arrangement allows for a high strength, quality gasket seal suitable for use on standard flage assemblies, valves, pumps, heat exchangers and other similar services.

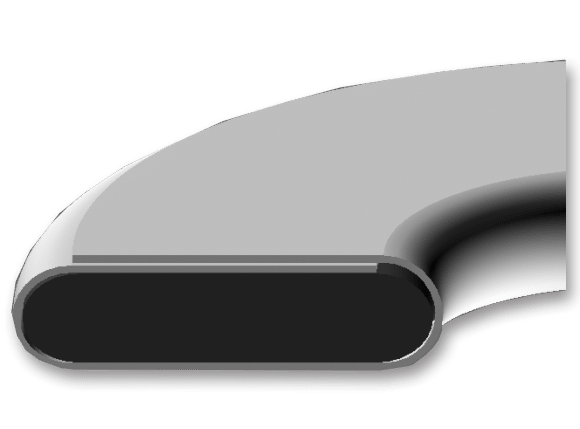

Single Jacketed Gaskets

Filler material is enclosed in a metal jacket that covers the inside and outside diameters of the gasket and the contact surface on one side. Ideal for comparatively narrow circular on non-circular flanges with large diameters as in boilers, compressores, pumps, and gasoline engines. Not especially recommended for standard pipe flangers.

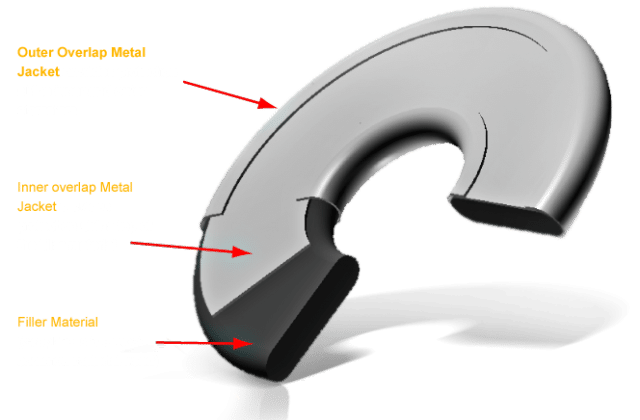

Overlapped Single Jacketed Gaskets

Overlapped Single Jacket- Filler completely enclosed in a one-piece metal jacket. Ideal for applications like pump heads where a completely enclosed gasket is required because of temperatures encountered, and narrow flange widths.

Double Jacketed Gaskets

Double Jacketed Gaskets- Filler material is completely enclosed by a two-piece metal jacket that covers both inside and outside diameters of the jacket and the contact surfaces on both sides. Ideal for applications in which temperatures as high as 1650F are encountered as boilers, heat exchangers, and similar applications. Available in all standard pipe sizes. There is virtually no limit to gasket diametersor to rib configuration that can be inserted.

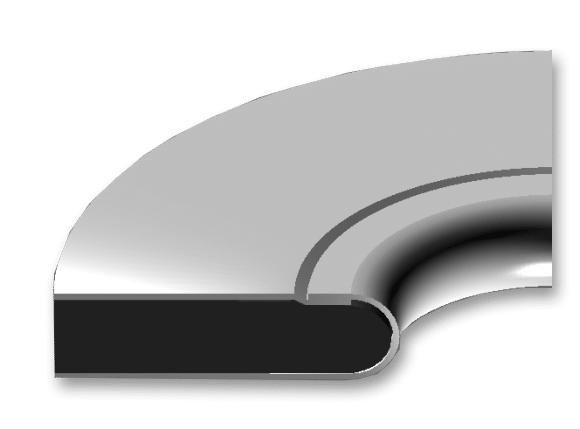

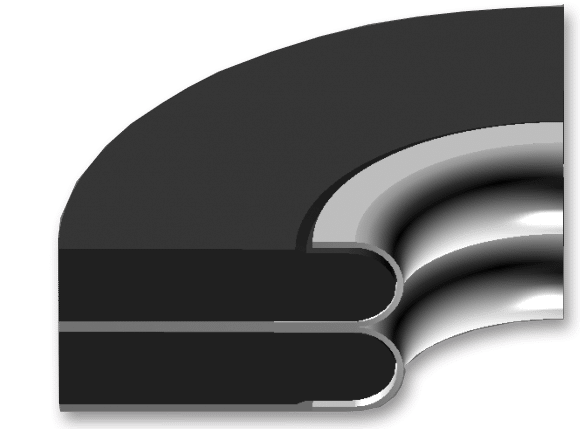

Double shell Gaskets

Double Shell Gaskets- Filler material is completely enclosed by two reversed wrap-around shells.Overlapping metal shells provide superior flange support at inside and outside diameters and better resistance to high pressures and temperatures. Ideal for application where a more rugged gasket than Style 123 is required. There is virtually no limit to gasket diameters. Minimum flange width is 1/4.

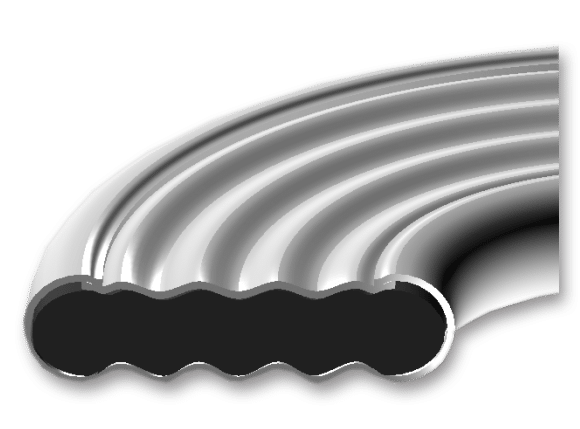

Corrugated Double Jacketed Gasket

Corrugated Double-Jacketed Gaskets- Similar to Style 123, except that two-piece metal jacket is formed of corrugated metal rather than flat metal. More resilient than Style 123. Corrugated jacket forms multi-Seals across the flange.Ideal for temperature cycling applications.

French Type Gaskets

French-Type Gasket- Filler material is enclosed in a metal jacket that covers the inside diameter of the gasket and completely covers contact surfaces on both sides. Ideal for small-diameter narrow flange circular and non-circular applications, such as vaccum seals and valve bonnels, where an unbroken metal surface across the full face is required

Two Piece French Type Gaskets

Two-Piece French-Type Gaasket- Identical to style 130, except that inside diameter of the gasket is protected by overlapped construction of the two-piece metal jacket. Ideal for wide or irregular-shaped flanges in virtually any diameter. Minimum flange width is 1/4″. Less expensive than styles 130 or 123..

Two Piece French Type Gaskets

Two-piece French-Type Gasket- Identical to Style 130, except that a three-piece construction is used for the metal jacket. Ideal for wide or irregular-shaped flanges in virtually and diameter.

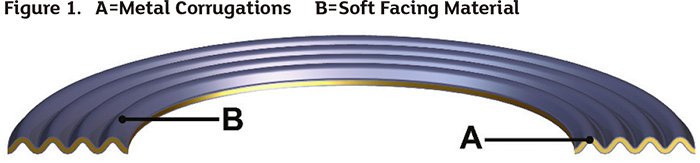

Corrugated Metal Gasket

Corrugated Metal Gaskets- Corrugations provided multi-seals across the face of the gasket. Designed for applications to 500 psi. Pitch of the corrugations can be 1/8″ , 3/16″ , or 1/4″. Three concentric corrugations on each side of the gasket are suggested Where practical a flat area should be left on each side of the corrugations.

Single Jacketed Gaskets

Single-Jacketed Gasket- Corrugated Metal Gaasket enclosed in a flat metal jacket that covers the inside and outside diameters of the gasket and the contact on one side.

Corrugated Double Jacketed Gasket

Double Jacketed Corrugated Gasket- Corrugated Metal Gasket completely enclosed in a two piece metal jacket that covers both inside and outside diameters of the gasket contact and contact surface on both sides.